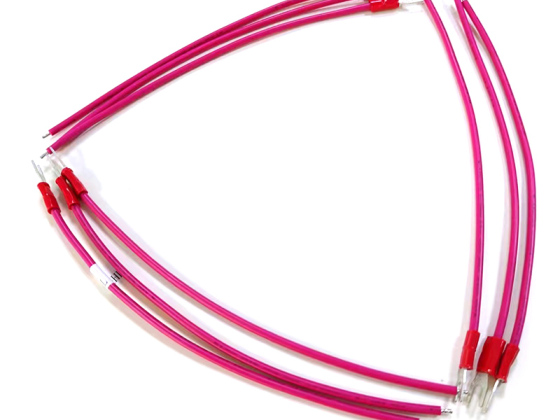

Manufacture wire harness UL3173 18AWG with fiber tube Cable Harness

Manufacture wire harness UL3173 18AWG with fiber tube Cable Harness.Our UL3173 18AWG custom wire harness is engineered for high-performance applications requiring superior electrical conductivity and heat resistance. Available in custom lengths ranging from 100mm to 150mm, these single core cable assemblies are tailored to fit your precise specifications.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

Product Name | Custom Wire harness and Cable assembly |

Wire Type | UL Wire, VDE Cable, Automotive Wires, Dran Chain Cable, Medical Cable ect. |

Wire Size | 2AWG-32AWG, 0.01mm²-50mm² are available |

Wire Cores | 1 Core~50 cores are available |

Conductor | Bare Copper, Tinned Copper, Silver Plated, Gold Plated wire |

Rate Temperature | 80℃, 105℃, 125℃, 180℃, 220℃, 300℃ (176°F- 572°F) |

Certification | UL, VDE, CE 3C or Customize Special Cables |

Connector Type | TE, Molex, JST, Yeo nho, Sumi tomo, Ya zaki or others |

Protection Pipe | PVC tube, Corrugated pipe, Shrink Tube, Braid Tube |

Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV Cable, Acid and alkali-resistant cable are available. |

Plug Molds | We have 300+ Plug molds, many plug we have tooling. |

Industries | Autmobiles, Electronics, Machines, Lighting, New energy |

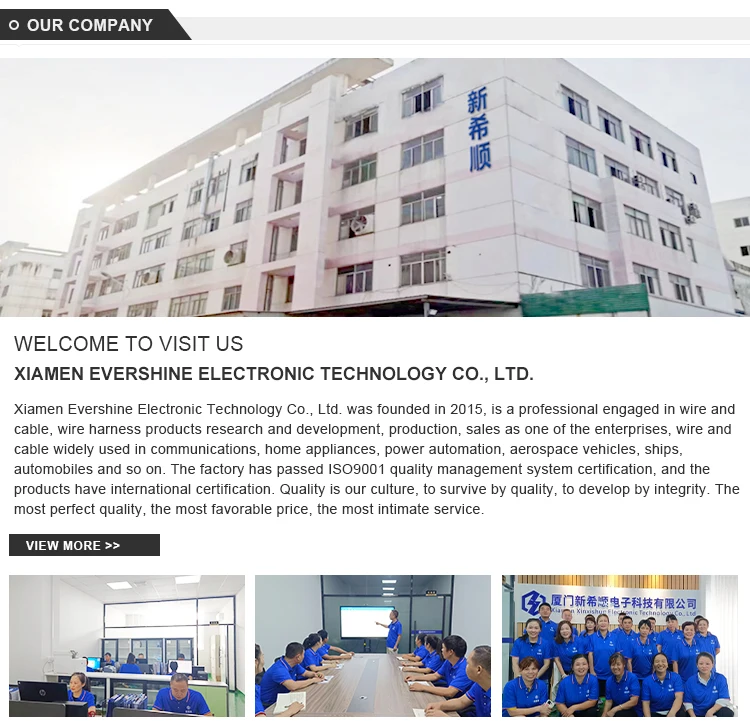

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable,

wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used

in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design,

custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness,

over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office

equipment, communications, household appliances, industrial automation, automobile, etc.

How to do a wiring harness?

The process of producing harness wire consists in precise connection of cables with terminals and insulating elements in a way that allows current to flow from one point to another. This process may include connecting wires with connectors, soldering, gluing, crimping or using other methods of connecting wires.

What is a cable harness assembly?

A cable harness, also known as a wire harness, wiring harness, cable assembly, wiring assembly or wiring loom, is an assembly of electrical cables or wires which transmit signals or electrical power.

Much of the equipment used in the automotive industry, aerospace, manufacturing, and construction relies on an abundance of electronic equipment to operate. With much of this equipment connected by complicated series of cables and wires, it is necessary for many design engineers to implement a cable harness assembly to best bind together the exposed wires, providing protection and a more organization to internal components. Here is some more helpful information on how a cable harness assembly works, and some of its most common applications.

The primary purpose of a cable harness assembly is to help concentrate a large number of cables and wires in a variety of equipment, as to best organize and protect the electronics. Since many of the wires and cables can extend great lengths, binding them together helps prevent excess wires being exposed and loose in your equipment. For applications with moving parts, like automobile engines and assembly lines, loose cables could be an exceptionally prominent safety hazard.

What is the meaning of harness wiring?

A wire harness is a specially designed system that keeps numerous wires or cables organized. It is a systematic and integrated arrangement of cables within an insulating material. The purpose of the wiring assembly is to transmit a signal or electrical power.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.