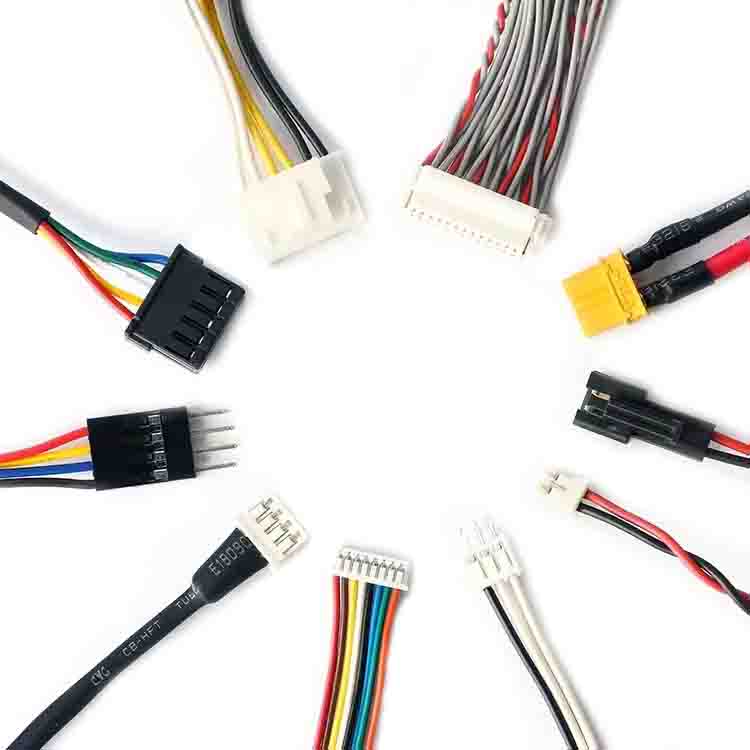

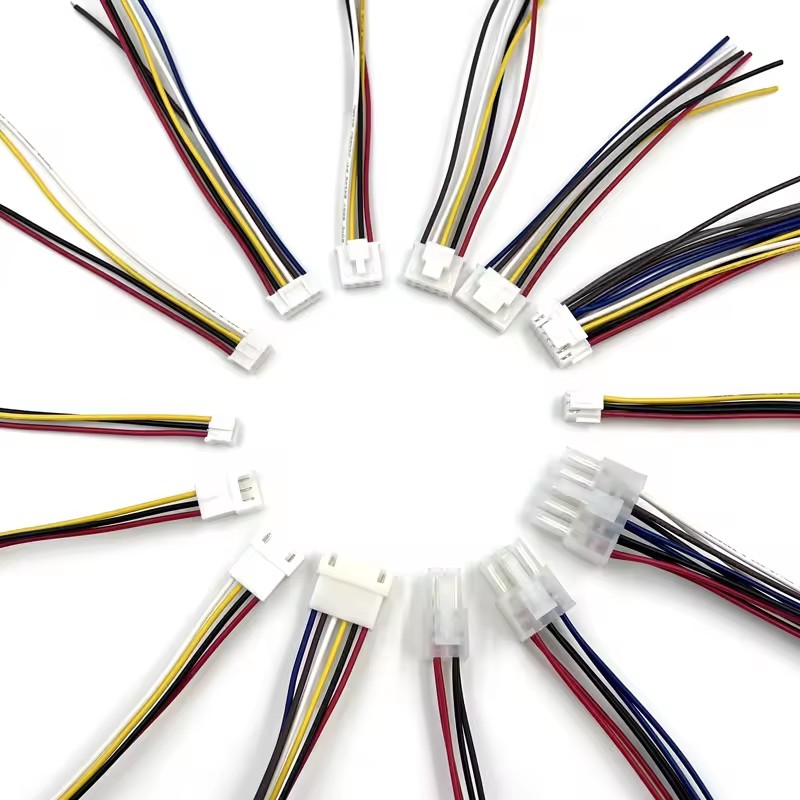

Custom High Quality Connectors Wiring Harness Cable Terminal Wire Harness

High quality JST and Molex connector wire harness terminal wires produced by professional wire harness factories.

Provide in-depth OEM and ODM customization services, which can be customized and produced according to customer needs.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

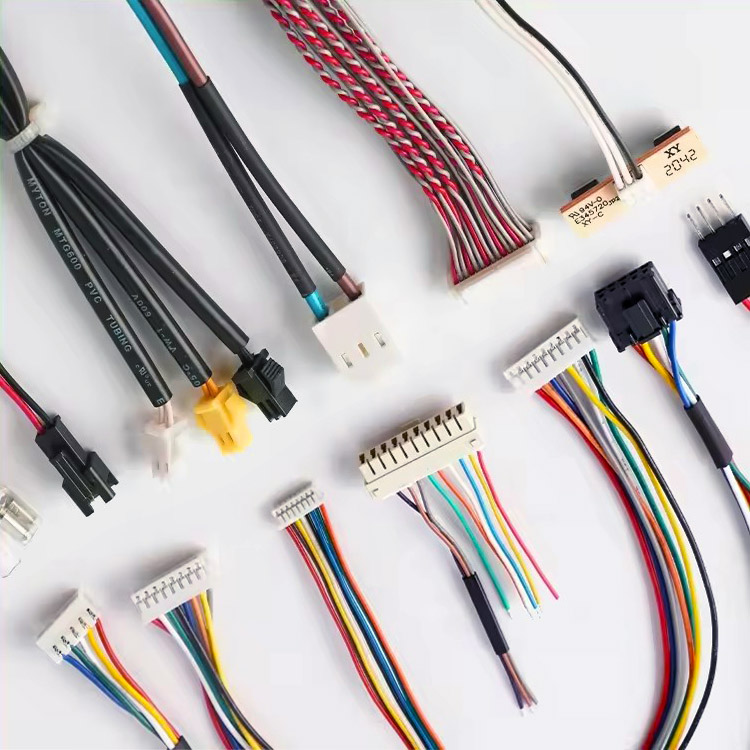

Product Name | Custom High Quality Connectors Wiring Harness Cable Terminal Wire Harness |

Wire Type | UL Wire, VDE Cable, Automotive Wires, Dran Chain Cable, Medical Cable ect. |

Wire Size | 2AWG-32AWG, 0.01mm²-50mm² are available |

Wire Cores | 1 Core~50 cores are available |

Conductor | Bare Copper, Tinned Copper, Silver Plated, Gold Plated wire |

Rate Temperature | 80℃, 105℃, 125℃, 180℃, 220℃, 300℃ (176°F- 572°F) |

Certification | UL, VDE, CE 3C or Customize Special Cables |

Connector Type | TE, Molex, JST, Yeo nho, Sumi tomo, Ya zaki or others |

Protection Pipe | PVC tube, Corrugated pipe, Shrink Tube, Braid Tube |

Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV Cable, Acid and alkali-resistant cable are available. |

Plug Molds | We have 300+ Plug molds, many plug we have tooling. |

Industries | Autmobiles, Electronics, Machines, Lighting, New energy |

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable,

wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used

in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design,

custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness,

over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office

equipment, communications, household appliances, industrial automation, automobile, etc.

How is a wiring harness created?

The electronic contents inside an automobile are increasing day by day and posing newer challenges in terms of managing the wiring harnesses that connect them.

A wire harness is a specially designed system that keeps numerous wires or cables organized. It is a systematic and integrated arrangement of cables within an insulating material.

The purpose of the wiring assembly is to transmit a signal or electrical power. Cables are bound together with straps, cable ties, cable lacing, sleeves, electrical tape, conduit, or a combination thereof.

Rather than manually routing and connecting individual strands, the wires are cut to length, bundled, and clamped to the terminal or connector housing to form a single piece.

The wiring harness is created in two stages. It is designed in a software tool first and then the 2D and 3D layout is shared with manufacturing plants to build the harness.

The specific process of vehicle wiring harness design involves the following steps:

First, the electrical system engineer provides the functions of the entire electrical system, including the electrical load and related unique requirements. The state of the electrical equipment, the installation location, and the form of connection between the wiring harness and the electrical equipment are all key considerations

From the electrical functions and requirements provided by the electrical system engineer, the complete vehicle electrical schematic is created by adding components required for a function and connecting them together. The functions which are commonly used across multiple vehicles in an architecture platform are stored together.

After the schematic is defined, the wiring harness design is created. In one platform, the end customers can have a variety of requirements. It is very time-consuming and expensive if different designs are created for each end user’s requirements separately. So, the designer takes care of the multiple variants while designing the wiring harness.

At the end, a 2D representation of all the wiring designs is created to show the way different wires are bundled and how the bundles are covered to secure the wires. End connectors are also shown in this 2D diagram.

These designs can interact with 3D tools for the import and export of details. The wire lengths can be imported from the 3D tool and the end-to-end connection details are exported from the wiring harness tool to a 3D tool. The 3D tool uses these data to add passive components such as straps, cable ties, cable lacing, sleeves, electrical tape, and conduits in relevant locations and send them back to the wiring harness tool.

After the design is completed in software, the wire harness is manufactured in the manufacturing plant starting from the cutting area then the pre-assembly area, and finally in the assembly.

what is cable harness?

A cable harness, also known as a wire harness, wiring harness, cable assembly, wiring assembly or wiring loom, is an assembly of electrical cables or wires which transmit signals or electrical power.

Otherwise referred to as a cable assembly, wire harness, wiring loom, or wiring assembly, a cable harness is an assembly of electrical wires or cables that conveys electrical power or signals. The cables are tied together with one or more of the following: cable ties, straps, electrical tape, cable lacing, conduit, a weave of extruded string, or sleeves.

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

what is a spiral cable assembly?

The spiral cable connects electrical circuits in the steering column to components located in the steering wheel which include steering wheel controls, horn switch, and airbag assembly.

Spiral cables, also known as coiled cables, are a reliable and flexible solution for many applications. Due to their expandability and flexibility, they can be adjusted to different length requirements without knotting or bending.

What is spiral wire?

A serial cable or RS-232 cable is a cable used to transfer information between two devices using a serial communication protocol. The form of connectors depends on the particular serial port used. A cable wired for connecting two DTEs directly is known as a null modem cable.

Group of wires or cables arranged in such a way so as they make a single unit is termed as cable assembly, used to transmit power or information signals and provide power to various individual cables, called Cable Assembly.

PVC Spiral Cable: high economy, low mechanical and chemical resistance and suitable for light industry and computers

PUR Spiral Cable: good elastic force, excellent mechanical and chemical properties and suitable for machinery and power tools

PUR Shielded Spiral Cable: very good chemical properties, resistant to EMI and used for medical, semiconductor chips and Nano Technology.

What is a cable harness assembly?

A cable harness, also known as a wire harness, wiring harness, cable assembly, wiring assembly or wiring loom, is an assembly of electrical cables or wires which transmit signals or electrical power.

Much of the equipment used in the automotive industry, aerospace, manufacturing, and construction relies on an abundance of electronic equipment to operate. With much of this equipment connected by complicated series of cables and wires, it is necessary for many design engineers to implement a cable harness assembly to best bind together the exposed wires, providing protection and a more organization to internal components. Here is some more helpful information on how a cable harness assembly works, and some of its most common applications.

The primary purpose of a cable harness assembly is to help concentrate a large number of cables and wires in a variety of equipment, as to best organize and protect the electronics. Since many of the wires and cables can extend great lengths, binding them together helps prevent excess wires being exposed and loose in your equipment. For applications with moving parts, like automobile engines and assembly lines, loose cables could be an exceptionally prominent safety hazard.

How to do a wiring harness?

The process of producing harness wire consists in precise connection of cables with terminals and insulating elements in a way that allows current to flow from one point to another. This process may include connecting wires with connectors, soldering, gluing, crimping or using other methods of connecting wires.

Wire Harness Assembly Process:

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering.

Labeling and Marking.

Final Quality Check and Packaging

Welcome to send us the details drawing,best service for you.